Sims Recycling

| Response to NYC/DOS-RFP to develop Anaerobic Digestion Facility | Brooklyn, New York City, NY | 2012 |

City Soil reviewed and ranked potential vendors and representatives of anaerobic digestion technologies and supporting infrastructure and equipment for world's largest recycling company. Assessed anaerobic digestion (AD) systems for compatibility with clients' privately operated marine terminal recycling facility and the anticipated feedstock for the facility.

City Soil provided consulting services for Sims in preparation for the company's response to the New York City Department of Sanitation's request for proposals to develop an anaerobic digestion facility to serve New York City. Reviewed technology, capital and operational costs and footprint requirements for single-stage and two-stage High Solids Anaerobic Digestion for a 100-150 ton per day facility. Assessed potential vendors and representatives of silo, bay and tube technologies. Conferred with AD specialists and CSG team members regarding vendor qualifications, technological and team capacity, corporate structure and US representation. Identified key performance criteria for AD systems including; system sensitivities to MSW preprocessing functions, contamination of feedstock materials, startup cycle duration, electrical power consumption for operations, moisture removal systems and end product quality. Assessed comparative benefits of shortlisted AD system digestate management scenarios, end-product composting and biofiltration scenarios. Evaluated odor control systems: footprint for biofilter, performance, siting criteria, and costs for conventional, hybrid systems, and synthetic biofiltration media.

University of New Hampshire Agriculture Experiment Station

| Durham, NH | 2012 |

City Soil lends its operational expertise to a doctoral research project at University of New Hampshire. The research is developing a sustainable model for processing New England dairy manure and bedding in an enclosed aerated compost system that employs the Agrilab Isobar heat recovery technology.

This project is conducted at the UNH Organic Dairy Research Farm, managed as an agro-ecosystem that includes all biological, physical and human related components. The research is evaluating the use of locally produced wood shavings, integrating a sustainable forestry program with the responsible management of agricultural nutrients. This farm offers a unique land grant university based platform for research and education across many disciplines, exploring value-added opportunities for the region's organic and conventional farm operations. City Soil is working with lead researcher to secure resources for biothermal greenhouse to be coupled with the operation.

Learn more from the University of New Hampshire

Save That Stuff, Inc.

| Anaerobic Digester Feasibility Study | Charlestown, MA | 2010 |

Positioned Save That Stuff's subsidiary STS Organics to form strategic partnerships to develop commercial-scale anaerobic digestion (AD) and composting operations integrated with bioenergy recovery.

Focused on determining the feasibility of a facility in Charlestown, including due diligence and site visits to European AD systems. Solicited price quotes from European and US technology vendors and developers, then reviewed and ranked 16 responses. Negotiated with site owners, abutters to potential sites, and potential investors. Coordinated meetings with USEPA, Massachusetts DEP, MDAR, DOER, the Boston Environment Department and Public Works Department, and Massport. Developed DEP permitting pathway for air quality and prepared a draft Determination of Need application for exemption from Solid Waste Facility Site Assignment. Developed proprietary financial models and conducted food sector feedstock sourcing. Prepared conceptual design and preliminary engineering assessment of co-located greenhouse and biofilter facilities, and local and regional horticultural applications.

Mass Natural Fertilizer Corp.

| Westminster, MA | 2007-2008 |

Mass Natural was the first large-scale private organic recycling facility permitted by the Commonwealth of Massachusetts. City Soil worked with Demeter Bioenergy to secure a $40,000 grant from the Massachusetts Technology Collaborative and evaluate the feasibility of establishing an anaerobic digester at Mass Natural Fertilizer Corp.'s family owned composting operation.

Demeter Bioenergy's team worked with experienced specialists to predict the quantity of power that could be generated from energy-rich feedstocks in the regional waste stream and determine the cost of interconnection with the power grid. City Soil reviewed agricultural sources of manure and organic residuals likely to be available to Mass Natural. Developed the preliminary design and cost estimates for an enclosed, in-vessel composting system that could be constructed in conjunction with the AD facility at the 25-acre site. Projected electrical energy used to power composting equipment and air handling fans for biofilters. City Soil also developed cost and revenue projections for a linked greenhouse business to grow produce and ornamental crops, using AD generated heat and power for lighting and ventilation. City Soil worked with MDEP to determine modifications and approvals that would be required to the existing Solid Waste Facility Site Assignment for the composting facility. These were based on the projected quantities and classifications of new feedstocks and the Mass DEP air quality permit requirements for the recommended 848 kWh power generation equipment.

City Soil developed the preliminary design and costs estimates for an enclosed, in-vessel composting system that could be developed in conjunction with the AD facility, and the electrical energy used to power equipment and air handling fans. City Soil also developed costs and revenues projections for linked greenhouse business to grow produce and ornamental crops, using AD generated heat and power for lighting and ventilation. City Soil worked with MDEP to determine modifications that would be required to the existing Solid Waste Facility Site Assignment for the composting facility, based on the projected quantities and classifications of new feedstocks and the Mass DEP air quality permit requirements for the designed 878 kWh power generation equipment.

Rocky Hill Farm

| Saugus, MA | 2007 |

City Soil was hired by the Massachusetts Department of Environmental Protection's "Composting Technical Assistance for Farms and Facilities" program to evaluate in-vessel composting and anaerobic digestion options for an agricultural composting facility that has provided food waste diversion capacity for Boston for generations.

This work was one of a series of projects that City Soil has completed with funding from the MDEP and the USEPA, that include short term interventions and long term solutions to management challenges in building the Commonwealths food and yard waste composting capacity. City Soil provide remedial technical assistance for Rocky Hill Farm's existing 15 ton per day food waste composting facility in order to reduce and minimize nuisance odors associated with this outdoor facility. Identified different enclosed, in-vessel composting, and anaerobic digestion technologies appropriate for processing 50 tons per day of food waste at Rocky Hill Farm. Provided preliminary capital cost estimates, identified financing options for facility improvements, and a compost marketing plan. Developed monitoring plan and community outreach recommendations to improve neighborhood relations.

Intervale Community Farm and University of Vermont

| Burlington, VT | 2006 |

USDA Sustainable Agriculture Research and Education program funded technical assistance from City Soil to growers and composters in Massachusetts and Vermont. Project demonstrated value of compost for CO2 enrichment of high tunnels for growing early season tomato crop at one of Vermont's most successful Community Supported Agriculture programs. Coordinated research and monitoring with University of VT Graduate Program, The Intervale Foundation, and Intervale Compost Co.

New Alchemy Institute

| Falmouth, MA |

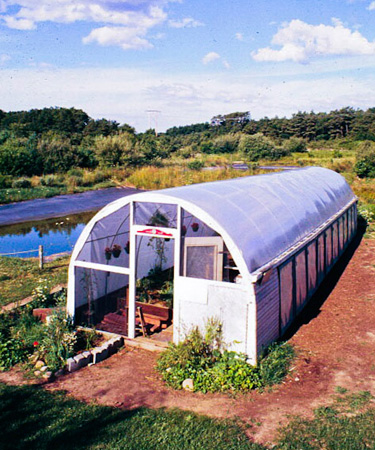

Developed prototype biothermal greenhouse and led team of international researchers in 4 year program including design, construction, monitoring and evaluation. Composted manures and bedding, yard waste, crop residue, aquaculture wastes, pre-consumer and post-consumer food wastes. Quantified heat production, CO2 concentrations, nitrogen dynamics and crop yields. Convened symposium of composting and greenhouse experts from Rutgers, Penn State, USDA and private sector in charting research and development agenda and commercialization of compost heat, CO2 enrichment and greenhouse production.